Rotor Inspection and Maintenance

Paragon Performance rotors are engineered with longevity and performance in mind, and are proven to last under extreme track / race conditions. High performance brake components are consumable products that must be maintained to ensure safe and optimum results. Regular schedule of inspection for fatigue, damage and wear must be employed.

The following inspection and maintenance procedure is highly recommended before and after each race / track day:

-

Inspect rotors for fatigue, damage and wear

-

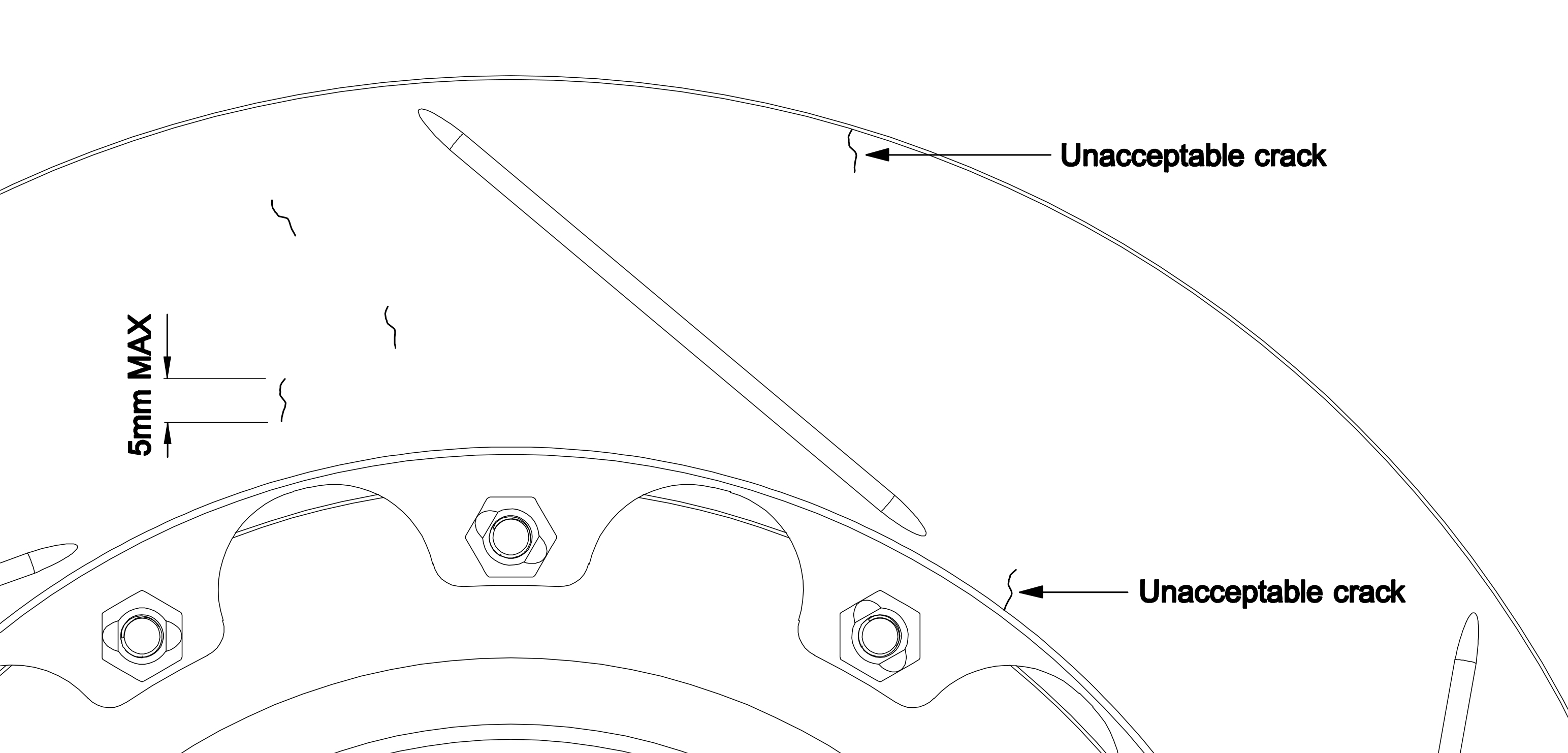

Inspect rotor surface (outside and inside). Check for cracks longer than 5 mm. After motorsport use, fine surface cracks (hairline cracks) shorter than 5mm are generally acceptable and are normal on rotors after track use. In case the crack begins from the external or internal diameter, even if the length is shorter, the rotor must be replaced.

***Regardless of rotor design, material, and manufacturer, minor thermal cracks could occur after motorsport use.

-

Measure and check if the rotor has reached / close to minimum rotor thickness. Minimum rotor thickness is engraved on the side of the rotor. DO NOT use rotor beyond minimum thickness. Replacement rotor rings are available for a reasonable cost.

-

Inspect and ensure proper clearance between brake pads, calipers, rotors, wheel hubs, and wheels.