Paragon Performance Rotors are available in a variety of face patterns, including straight slots, curved slots, plain, etc. Variables including length of slots, slot angle and depth of slots are all taken into consideration during development to ensure optimal braking performance. Most OEM rotors are plain-faced while slotted (grooved) rotors are the most common rotors in motorsport. Although, pad wear rate is slightly increased with slotted rotors, increased stopping power is achieved by providing more leading edges for brake pads to bite. A slotted rotor improves brake consistency by constantly cleaning the pad surface and dissipate heat generated & gases released when the pads come into contact with the rotors. Slotted rotor have a superior advantage over blank rotor in wet or raining conditions by preventing water films to form between the brake pad and rotor surface.

Drilled rotors are more prone to cracking compared to plain and slotted rotors, and are not recommended for motorsport use in most cases.

Straight slots:

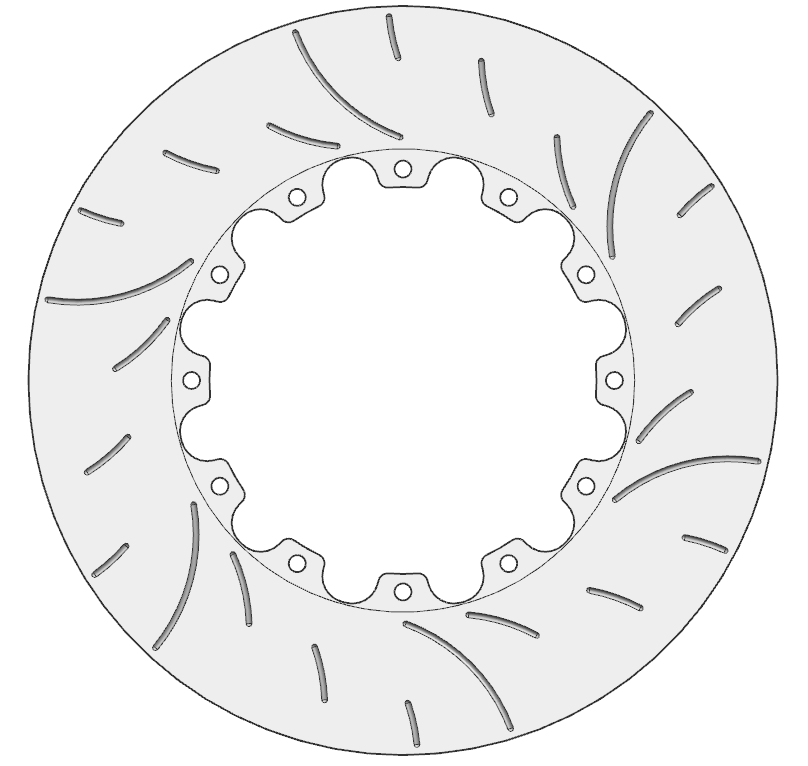

Straight slots improve brake modulation throughout the temperature range by providing consistent pedal feel. Improved resistance against thermal cracking. Lowest rotor and pad wear among all slotted / grooved rotor face patterns. Lower initial bite compared to C6 / CC24 / Z16 / Z24 face patterns. All Paragon Performance rotors come standard in straight slots. Most rotors with outside diameter smaller than 345mm are available in 6-slots configuration, while most rotors with 345mm or larger outside diameter are available in 8 slots. Suitable for most drivers / vehicles / intended use.

S6 (6 straight slots):

S8 (8 straight slots):

IS6 (6 inverted straight slots)

Inverted version of the commonly used S6 face pattern. Leading edges on the rotor are being cut into the brake pads in an opposite direction, providing higher braking efficiency. Increased pad and rotor wear.

When installed properly, the directional ventilation vanes will still face the correct direction, while the straight slots will be in a reverse direction compared to the regular S6 face pattern.

IS8 (8 inverted straight slots)

Inverted version of the commonly used S8 face pattern. Leading edges on the rotor are being cut into the brake pads in an opposite direction, providing higher braking efficiency. Increased pad and rotor wear.

When installed properly, the directional ventilation vanes will still face the correct direction, while the straight slots will be in a reverse direction compared to the regular S8 face pattern.

Curved Slots:

Rotors with curved slots are made to order only.

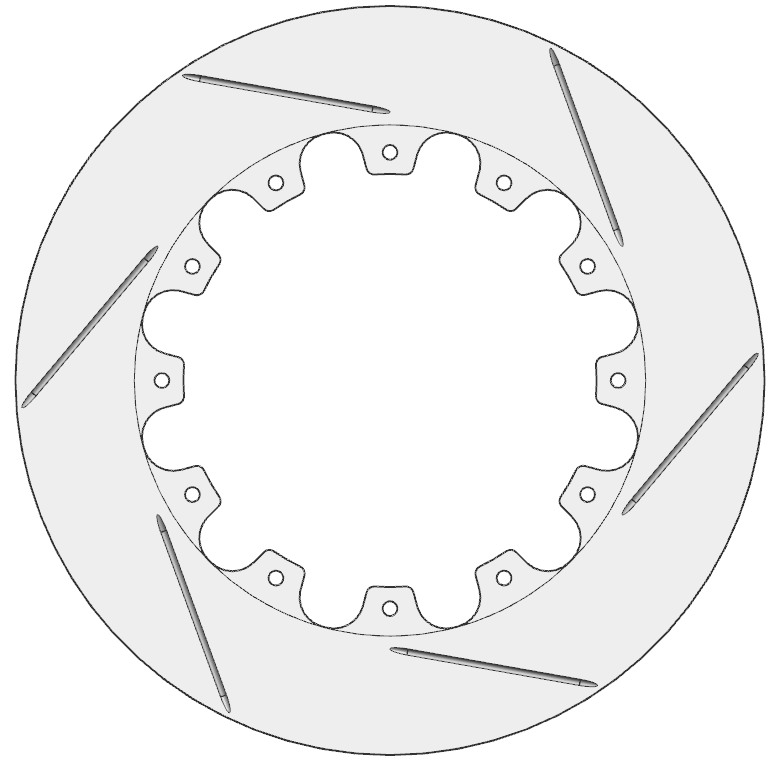

LC6 (6 curved slots):

Higher initial bite, and rotor / pad wear compared to rotors with straight slots. Lower initial bite, and rotor/ pad wear compared to CC24 / Z16 / Z24 rotors. Optimized for endurance races which demand better balance between braking power and wear.

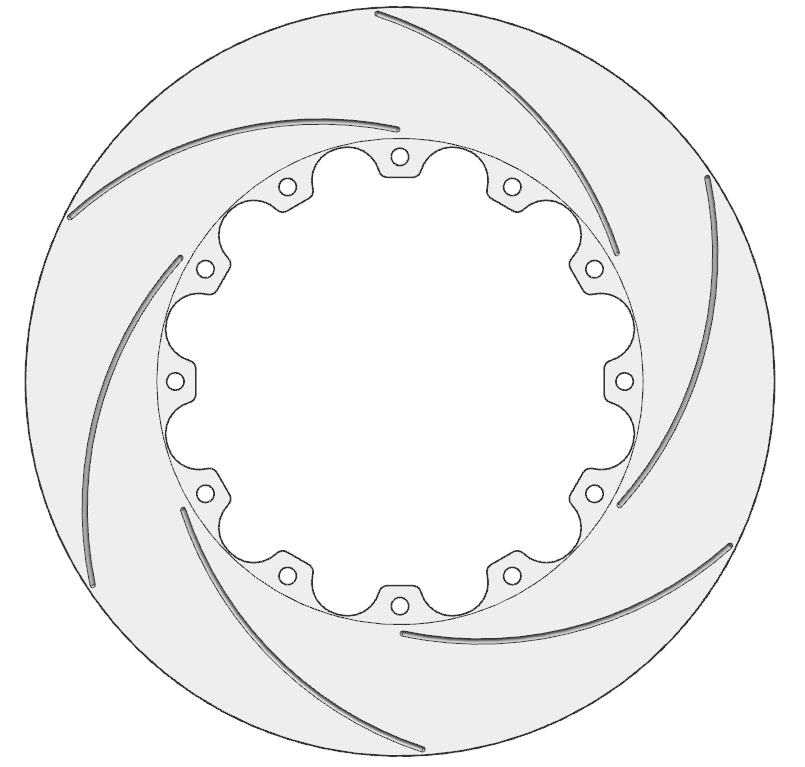

CC24 (24 curved slots):

More leading edges lead to higher initial bite and stopping power. Excellent brake modulation with smooth pedal release. Possibly higher rotor and pad wear.

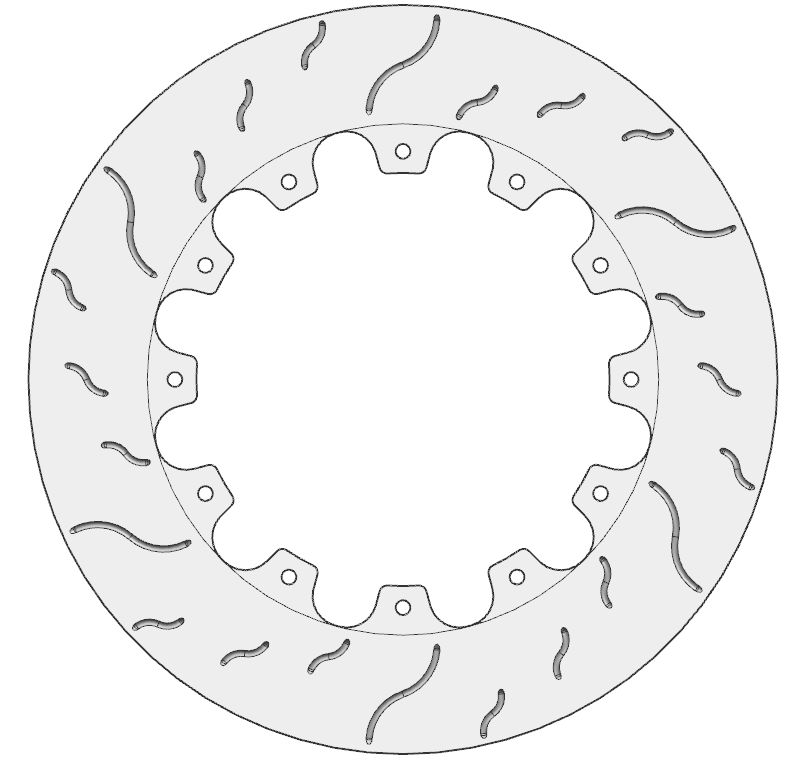

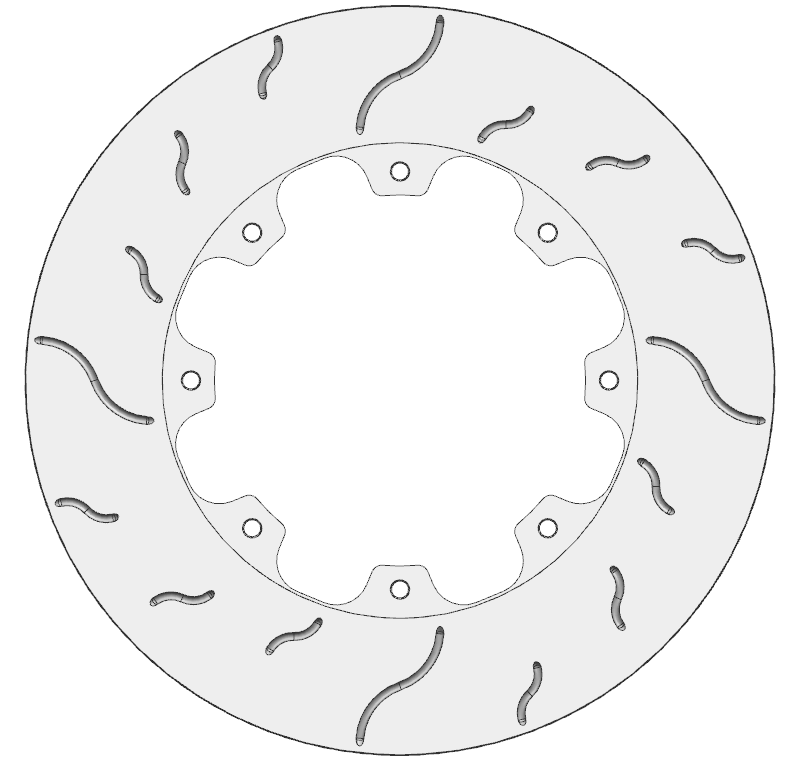

Z16 (16 "Z" shaped slots):

More leading edges lead to higher initial bite and stopping power compared to straight slots. Excellent brake modulation with smooth pedal release. Possibly higher rotor and pad wear. Utilized on rotors with smaller outside diameter.

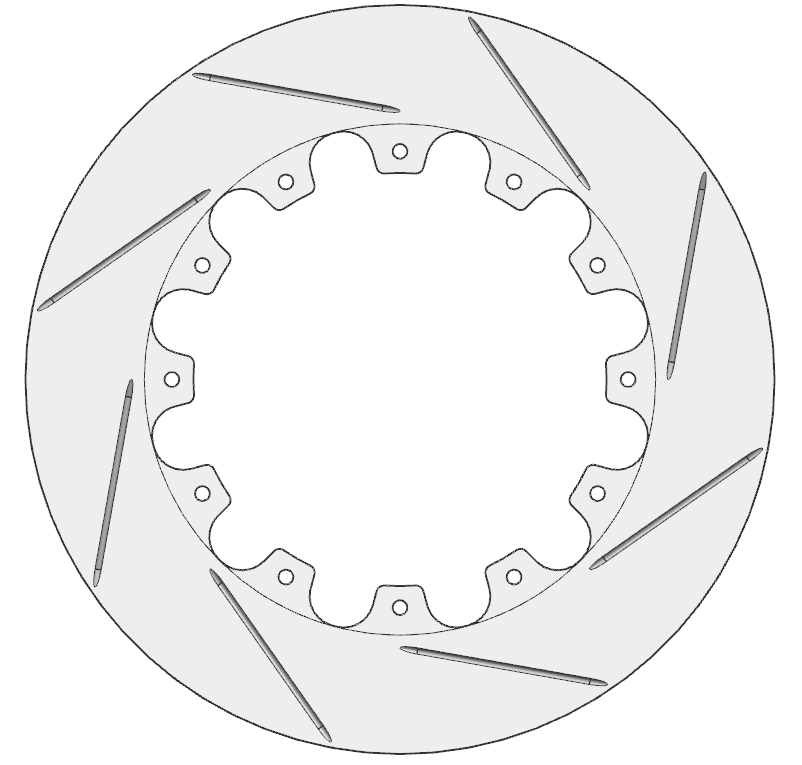

Z24 (24 "Z" shaped slots):

More leading edges lead to higher initial bite and stopping power compared to straight slots. Excellent brake modulation with smooth pedal release. Possibly higher rotor and pad wear.