After extensive development and track / race testing, Paragon Performance launched a new range of high performance rotor rings. Developed with performance, quality and longevity in mind, Paragon rotor rings offer superior braking and cooling efficiency optimized for track and race applications. While maintaining a competitive price, latest technologies and finest materials were used to ensure the rotor rings to perform and last under extreme conditions.

Floating 2-piece Design

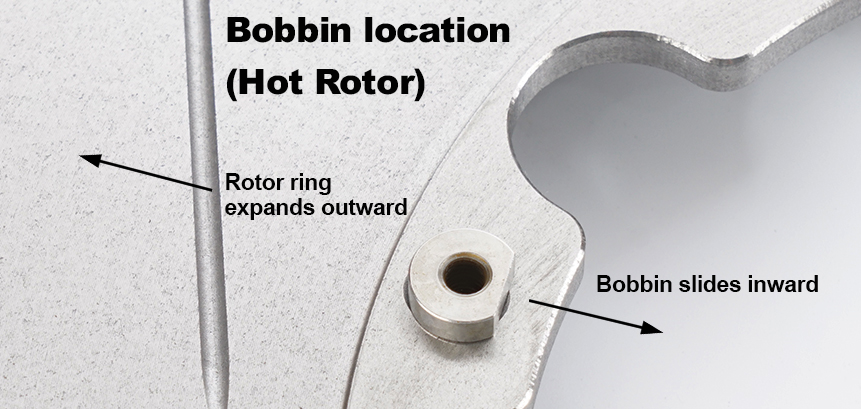

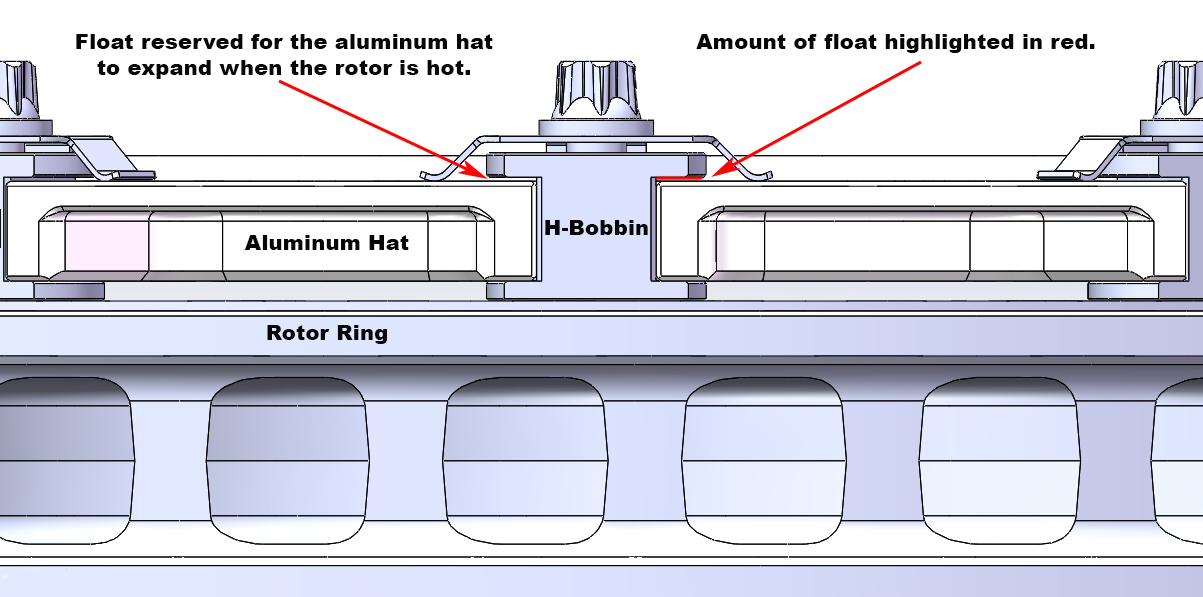

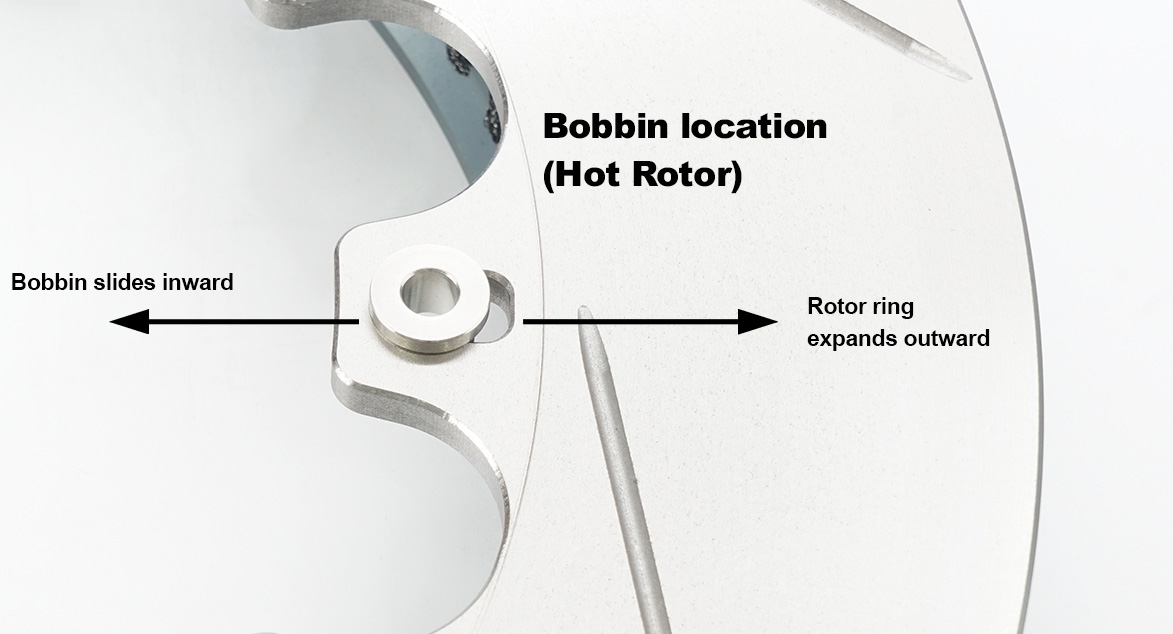

Under high temperature conditions, iron tend to expand and increase in diameter. In standard 1-piece rotors, every component is fixed and will easily distort under heat. With the use of floating hat & hardware, the floating 2-piece design allows expansion of the rotor assembly. This reduces deformation and cracking under extreme track conditions. The rotor is self-centered with the pads throughout the heat cycle and therefore allows consistent braking power and pedal feel.

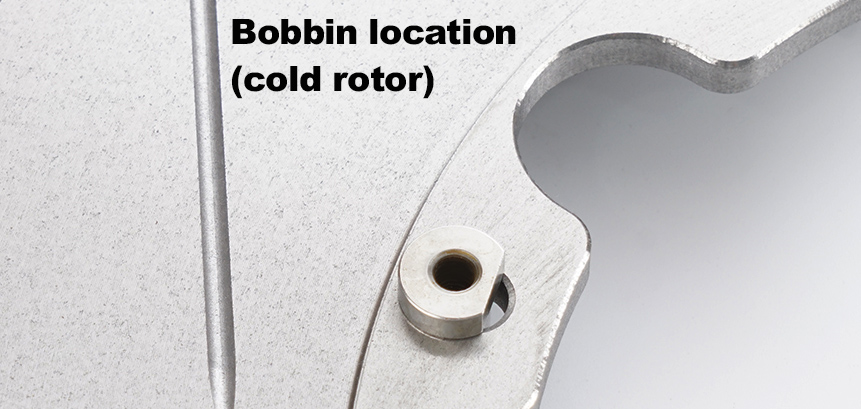

Rotors that utilize the H-Bobbin, T-Bobbin, and S-Bobbin mounting systems are fully-floating, which allow the rotor to "float" in both radial and axial directions according to temperature variations.

D-Bobbin:

H-Bobbin:

T-Bobbin:

S-Bobbin:

CM-250 Special Alloy Material

CM-250 is a special formulated high carbon alloy cast iron material exclusively available for Paragon Performance rotors. High carbon content allows the rotor to take a lot of heat and dissipate it quickly. Copper and exotic metals including molybdenum are added for improved strength, resistance to cracking, and thermal characteristics. After years of development and track testing, this material has been proven to perform under extreme track conditions. It allows for an optimized bite, longevity, high-temperature strength and heat-cycle durability. It is also heat treated to release stress in the rotor to avoid deformation and vibration, then turned by state-of-the-art CBN (Cubic Boron Nitride) machining. CBN machining ensure better break-in with new brake pads by allowing an even brake pad transfer layer deposition.

Vibration is also reduced as the rotor lateral run-out is kept within 0.03mm. All rotor rings went through rigorous balancing procedures and variations are kept within 2 grams.

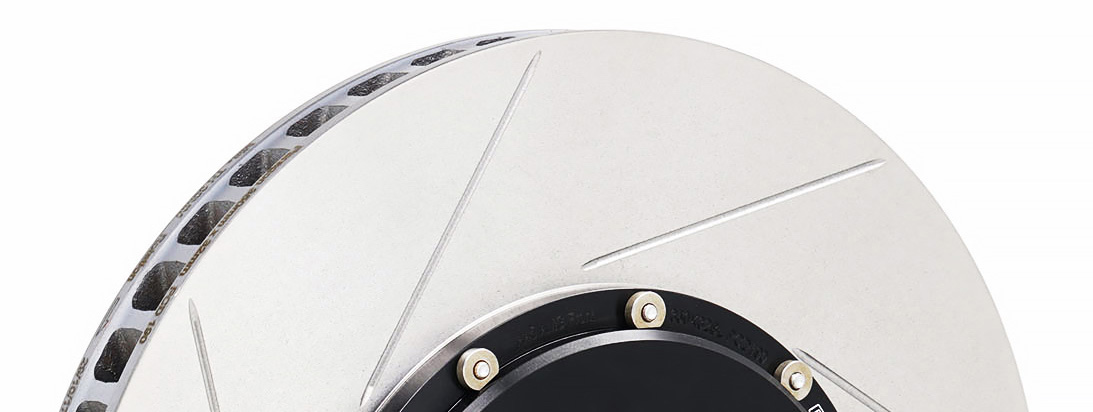

Slotted Friction Face

Paragon Performance rotor rings feature slotted design which improves brake consistency by constantly cleaning the contact surface and dissipate heat generated gases released when the pads come into contact with the rotors. Slotted rotors have a superior advantage over blank rotors in wet or raining conditions by preventing water films to form between the brake pad and rotor surface.

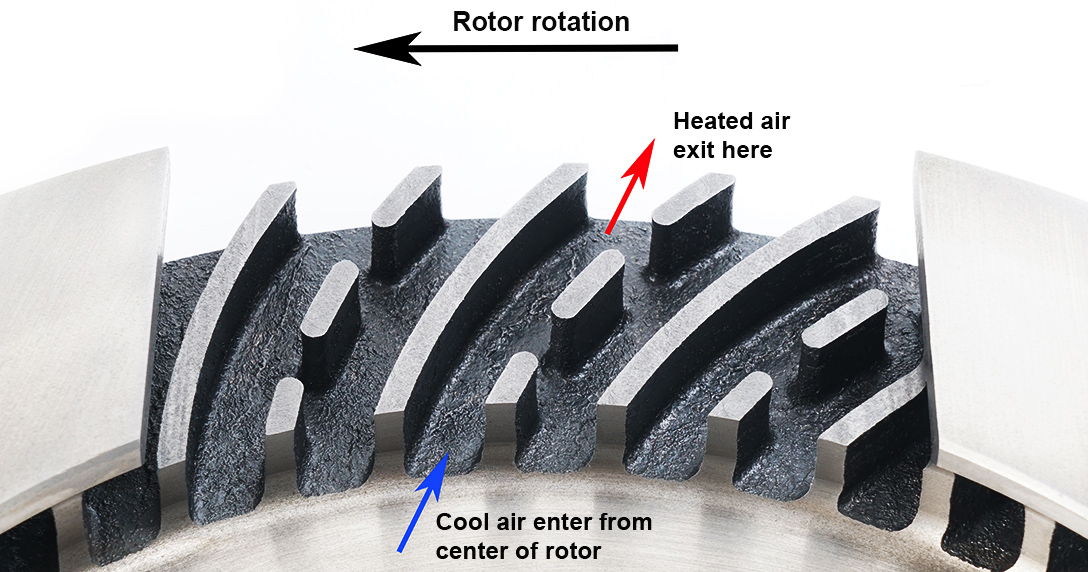

Curved Directional Ventilation Vanes

Most of our rotor rings feature 48 curved directional ventilation vanes, while some feature up to 72 vanes. The directional ventilation vanes create suction and turbulence, and guide cool air through the rotor to achieve greater thermal capacity and increased resistance to cracking under harsh track condition. Each rotor is left or right side specific and the ventilation vanes are optimized to spin in a particular direction to pump the maximum amount of cool air through the rotor. This design allows the rotor to run up to 30% cooler than O.E. rotors and increases cooling efficiency by up to 30% over standard 1-piece units. Brake fade and judder are minimized during extended sessions. This means the brake system can withstand heavier track usage and provide consistent braking performance laps after laps.

Use of brake ducts can further improve cooling on rotors with 2-piece design. Brake ducts force cool air into the center of the rotors, heated air can then exit the rotors through ventilation vanes.

Lower long-term maintenance cost

Although, the initial cost of 2-piece rotors are higher than standard 1-piece units, the long-term maintenance cost is significantly lower. With 2-piece design, you will only need to replace the rotor rings when the rotors are worn out. The aluminum hats and bobbins can be reused in most cases. 2-piece rotors will last longer due to improved thermal and cooling capacity. Under heavy usage, 2-piece rotors are less prone to cracking and deformation. Standard 1 piece rotors may last 2-3 track days, while high performance 2-piece rotors will last significantly longer.