Common brakes related issues

Brake system operating beyond temperature range:

Components in a brake system (calipers, rotors, brake pads, and brake fluid, etc) may not have the same optimum operating temperature range. However, when one of the components overheat, due to the components being closed packed and related, the other components may overheat as well. For motorsport / high performance driving applications, it is important to monitor and analyse the actual operating temperature of the components. Having an idea on each components’ operating temperature means we can have a clear idea about the cause of heat related issues.

Temperature paint kit with 3 different thermo-graphic colors is a simple yet effective way to monitor maximum rotor temperature. Each color will change respectively when the rotor reaches certain temperatures. In most cases the color with the highest temperature should not change.

Temperature indicator strips can be applied onto calipers to monitor maximum caliper operating temperature.

Infrared laser temperature guns and pyrometers can also be used, but may not be the best way to monitor peak operating temperatures.

***Refer to manufacturer’s guideline for optimum operating temperature ranges

To reduce overall brake system operating temperature, cooling devices like brake ducts can be employed. However, brake ducts are not suitable for every application as the operating temperature may be too low after installation of brake ducts.

Brake fade:

Brake fade can be caused by brake pads (pad fade) or brake fluid (fluid fade) reaching beyond its operating temperature. Depending on the material, brake pads have different temperature ranges ranging from ambient up to 2000 F (1093 C). Metallic pads generally have higher operating temperature limits compared to semi-metallic or ceramic pads. During pad fade, brake pads gas out and form an air cushion between the rotors and pads. The pedal will remain stiff, while there may be less or even no braking power. Pad fade is a temporary, and braking power will return to normal after the brakes have been cooled down. However, this may cause glazing on the rotor surface as the pads were too hot.

Using brake pads with higher optimum operating temperature can help reduce chance of brake fade. However, it is suggested that drivers can also pay attention to their driving style as sometimes brake fade occurs due to excessive and unnecessary use of brakes. Generally speaking, braking hard for 2 seconds will generate less heat than dragging the brakes for 4 seconds. Experienced drivers tend to brake harder for shorter duration to avoid generating excessive heat, and of course, for better lap times.

Soft brake pedal:

Soft brake pedal can be caused by air inside the brake system, low brake fluid level, or boiled brake fluid.

Brake fluid is hygroscopic and will absorb moisture. This will lower the boiling point of the brake fluid (wet boiling point). Any contamination / degradation will affect the performance, and may lead to brake failure. Therefore it is highly recommended to completely flush the brake fluid in regular intervals. DOT 5.1 brake fluids, a commonly used grade of brake fluid on the track, have dry boiling point at around 500 F (260 C), and wet boiling point at 356 F (180 C). Dry boiling point refers to the boiling point of fluid in its original state without moisture, while wet boiling point refers to the boiling point of fluid with a 3.7% water volume. The more water content inside the fluid, the lower the boiling point is.

During motorsport / high performance driving, drivers may experience gradual change in pedal stiffness from hard to soft. This may indicate boiling of brake fluid. Boiling of brake fluid is an irreversible process and need immediate attention to ensure the brake system to work properly. Fluid must be changed to restore safe and optimum braking performance.

Air inside the brake system can be caused by improper or incomplete bleeding. Bleeding refers to the process of evacuating trapped air or moisture inside the brake system. If the pedal is still soft after changing new brake fluids and initial bleeding, further bleeding the brakes could help, or it may mean that some components in the brake system (brake hose / calipers, etc) need to be inspected / replaced.

***Vehicles used for motorsport / high performance driving purposes usually require more frequent brake fluid change than the recommended intervals suggested by original equipment manufacturers. It is recommended to change fluids based on actual condition, instead of the distance driven.

Improper bedding:

Bedding-in is an essential process to mate the brake pads with the rotors to ensure full contact, establish proper friction surface (transfer layer), and release the organic binding material (resin) held inside the pads during manufacturing process. During bedding-in, there will be loss of friction due to the excess resin being released. This loss of friction is called green fade.

Improper bedding can lead to brake judder and vibration. During the improper bedding, uneven layer of material may be deposited onto the rotor surface and create high spots, which lead to thickness variations. Using new pads when replacing rotors can help minimize the chance of improper bedding by providing a new and even friction surface.

During bedding-in, it is essential to allow the brakes to cool between different series of stops. Overheating the brakes during bedding-in may lead to glazing on the brake pads. Do not apply emergency brakes right after bedding-in as this may distort the rear rotors. At times the brakes may overheat quicker than expected. Inspect rotors frequently.

With proper bedding, optimum braking power, wear characteristics, and modulation can be achieved.

Refer to our general bed-in procedure for more detail.

Noise, Vibration, and Harshness (NVH):

High performance automotive components tend to create more noise, vibration and harshness compared with OEM components. Most of our rotors utilize anti-rattle clips (McLaren spring clips), but keep in mind that NVH is still possible. Our engineers make every effort to eliminate NVH and it is uncommon on our OEM replacement 2-piece rotors. NVH related issues within the brake system can be caused by many factors including calipers and brake pads. In any unlikely case that NVH occurs, please contact us and we will be more than happy to assist you with the issue.

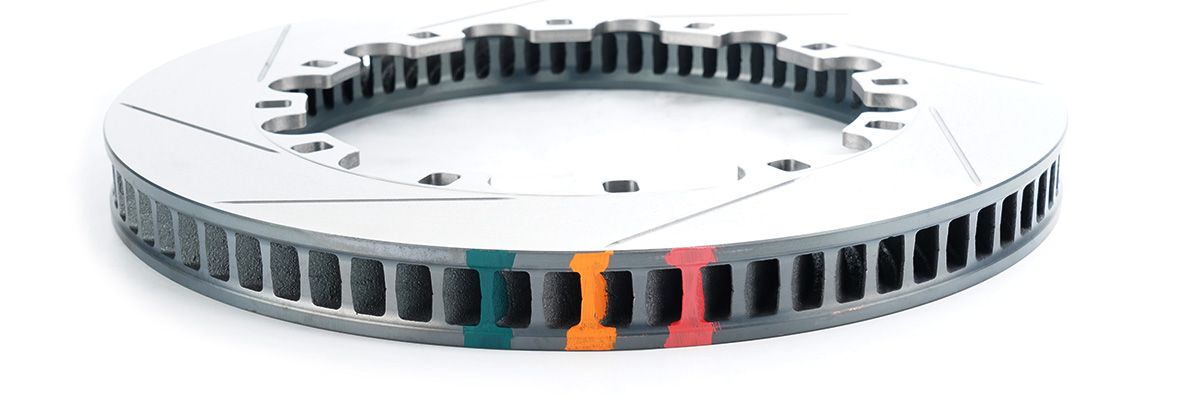

McLaren spring clips:

Imprinting:

Bedding-in process or heavy use of the brakes, eg: track use, generate tremendous heat in the brake system (rotor surface temperature can reach up to 1470F / 800C). After coming to a complete stop, if the brake pads are still in contact with the rotors, imprinting can occur. Hot rotors can melt the brake pads, and imprint a layer of pad material onto the rotors. The imprinted material will lead to thickness and friction coefficient variations on the rotor, and possibly lead to brake judder, poor modulation, and poor braking power.

To avoid imprinting, brake pads should not be in contact with hot rotors for extended period. For example, right after the bedding-in process or a hot session at the track, avoid using the emergency brakes. Instead, put the vehicle in gear or use a wheel chock.

When the rotor is hot, in the case that you need to stop for a short period (traffic lights during bedding-in / quick pit stop / red and black flag at the track), do not hold onto the brake pedal as long as the vehicle is not moving. This does not apply to regular street driving as regular street driving will not generate heat that is hot enough to cause imprinting.

A cool down lap with minimal use of brakes will help maximizing the longevity of the brake system, as well as other components on the vehicle. The key is to gradually lower the temperature of the brake system. Rapid change in temperature of metal components can accelerate deterioration.